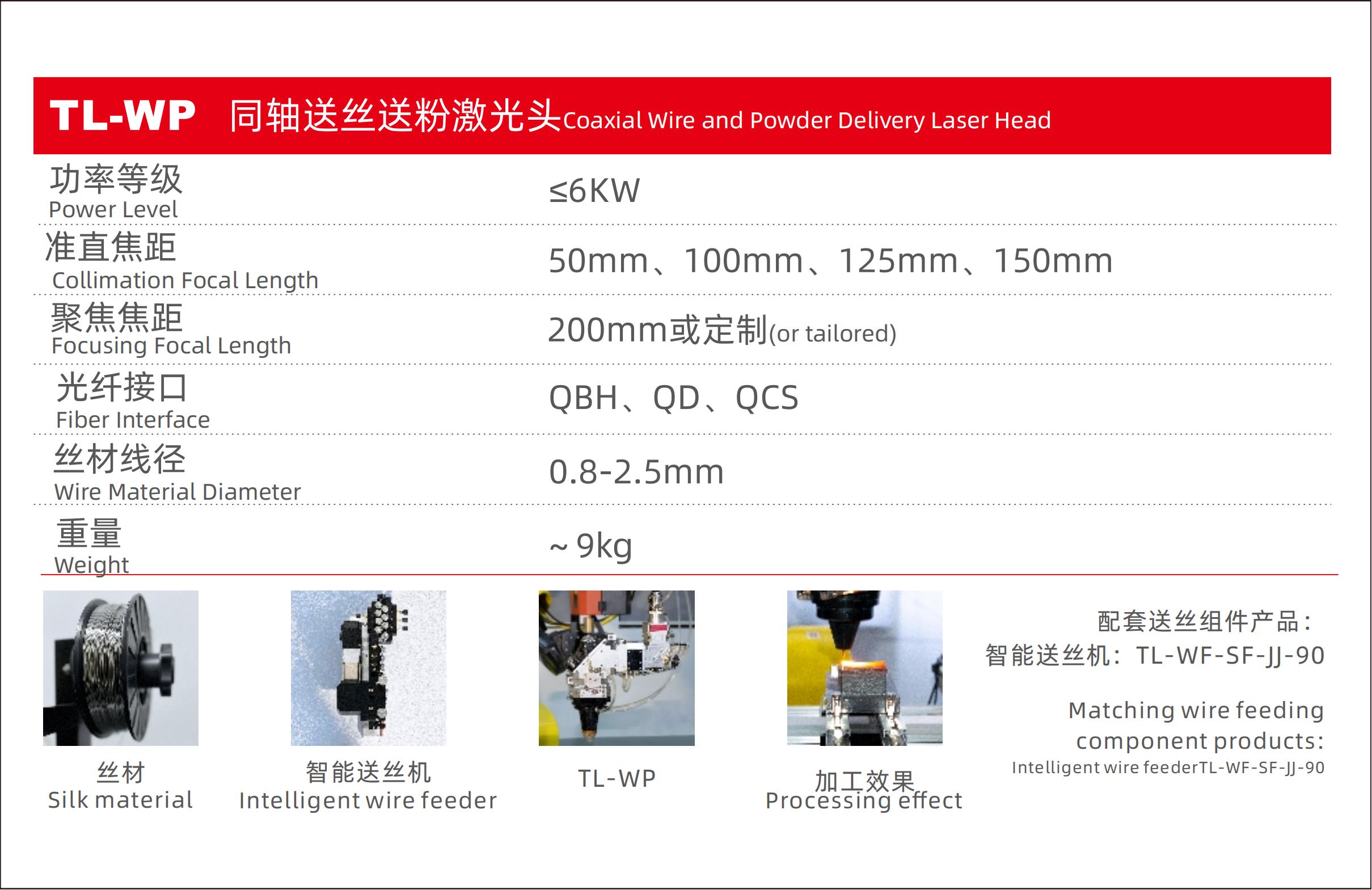

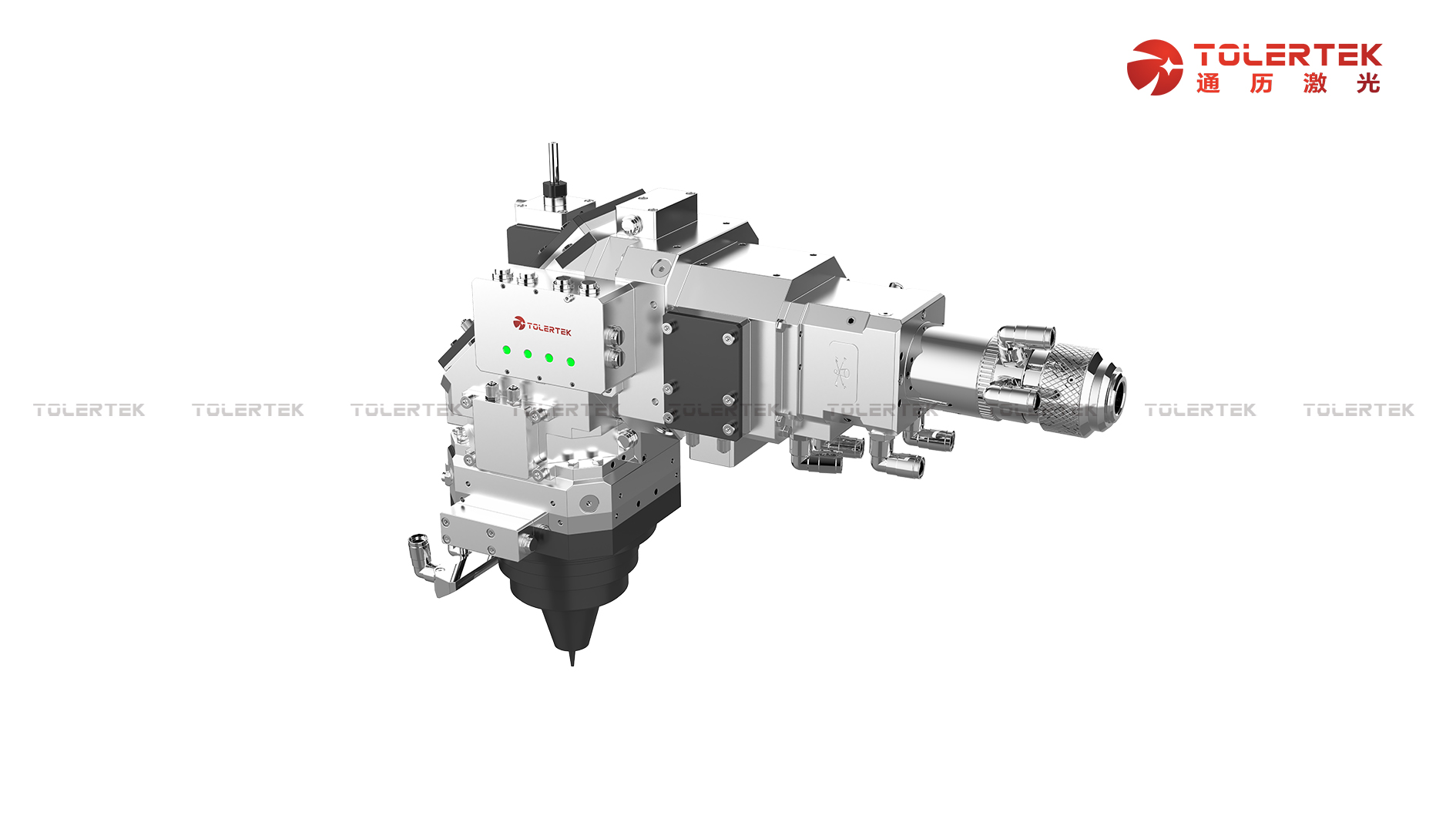

The TL-WP shapes the beam path into a hollow ring-shaped spot, enabling the coaxial delivery of metal wire (powder) from the center of the ring laser, providing a nearly perfect solution for light-encased wire (powder) applications. This inner wire (powder) and outer light approach to the melting process results in minimal splatter, making it especially suitable for laser applications such as additive manufacturing, surface cladding, and welding. The utilization rate of wire material delivered within the ring-shaped spot can reach 100%, and the utilization rate of powder processing materials can exceed 95%, with processing efficiency up to 400 cm/h. The hollow ring-shaped spot allows for the coaxial internal delivery of wire material (powder), with no directional or angular requirements for the processing trajectory. Optional infrared temperature measurement modules and CCD can provide comprehensive, multidimensional assurance of processing quality. The process is versatile across materials, including wire/powder forms of stainless steel, carbon steel, titanium alloys, nickel-based alloys, and more.

Widely applicable wire material.

Processing efficiency up to 400 cm³/h.

Optional intelligent detection sensors.

High sealing ensures clean lenses for a longer lifespan.

Wire material is coaxially integrated with no directional or angular requirements.